PRODUCT CENTER

CONTACT US

If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

Mobile

The galvanized steel coil Z275 is a double-sided galvanized carbon steel sheet. This is produced by a metal coating process that passes cold rolled coils through a bath filled with molten zinc. This continuous hot-dip plating or also known as electro-galvanizing is the main process that these carbon steel sheets must go through to produce coils and galvanized sheets. The process consists of applying zinc by electrolytic treatment. After the sheet is subjected to this treatment, a layer of zinc is adhered to the base metal through the iron and zinc bonding layer.

Z120 is the coating name, which means that the coating thickness on both sides is approximately 120g/㎡ or 36g/㎡ (three-point test) and 90g/㎡ (single-point test).

Z120 grade galvanized steel coil is coated with zinc to make it more durable. The working principle of the process is to immerse the coiled steel plate in a galvanizing tank filled with molten zinc. Through the continuous galvanizing process of the thin steel sheet, the galvanized coil is obtained. This type of steel has better formability and good paint adhesion in commercial or architectural use. Another method of producing galvanized steel sheet is through a hot-dip plating process. In this method, it is essential that the steel sheet is heat-treated at 500°C immediately after the exit of the can to form the alloy film coating.

Galvanized steel coils are covered with a zinc coating to provide corrosion resistance. G40 galvanized steel coil is a galvanized layer name or A653 standard specification specified in the hot-dip coating process galvanized (galvanized) or zinc-iron alloy (galvanized) steel sheet requirements. The G40 protective coating prevents moisture from reaching the steel structure, thereby improving the corrosion resistance of the steel. This can extend the life expectancy of the steel. G40 is the average coat weight and therefore provides moderate protection.

G60 is the coating grade of steel sheet after continuous hot dip plating process. G represents the "galvanized" or galvanized layer of the product. The number 60 refers to the thickness of the zinc around the steel sheet or the thickness of the entire double-sided coating. To get the amount of galvanizing on one side, you need to divide this number by two.

Galvanized steel sheet G60 is coated with molten zinc. After the continuous coating process at a speed of 600 feet per minute, the excess zinc on the steel plate is removed by high-pressure air. This is in order to produce the desired coating thickness. After cooling, the sheet is rolled into a roll, ready for manufacturing.

G90 refers to the coating type and coating weight on the steel coil or steel plate. "G" means that the coating is galvanized, that is, galvanized. Meanwhile, the number "90" represents the weight of zinc on the steel. G90 galvanized steel coil is hot-dip galvanized cold-rolled steel sheet to improve durability.

Galvanized zinc coil is based on cold-rolled steel plate, which is solidified by 55% aluminum, 43.4 zinc and 1.6 silicon at 600 ℃. It combines the physical protection and high durability of aluminum with the electrochemical protection of zinc. Also known as aluminized zinc steel coil.

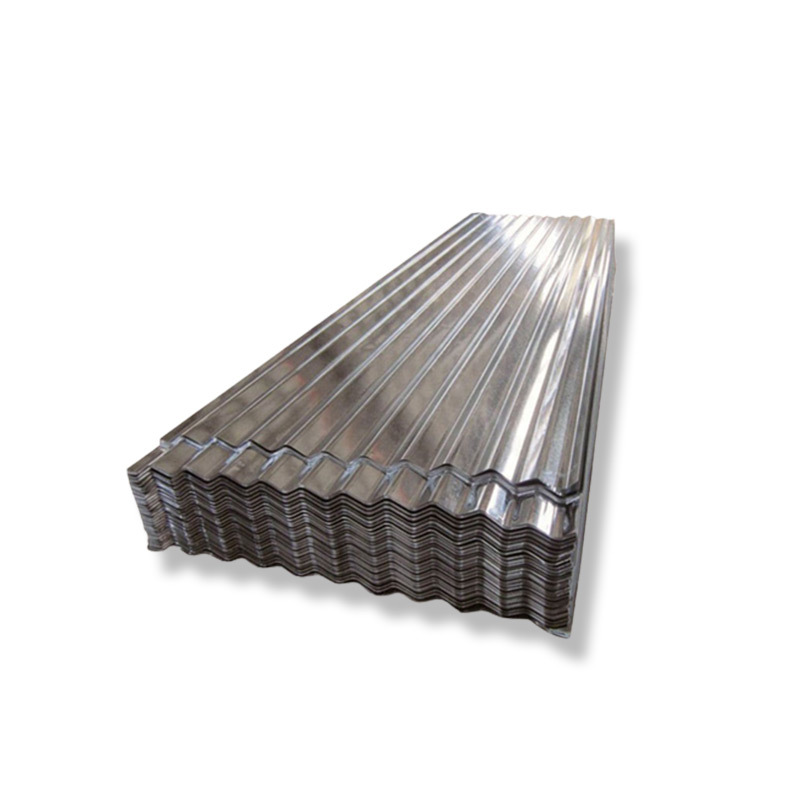

Galvalume Steel Corrugated Roof Sheet

Galvanized zinc metal roof panel is a kind of building material. It is made of aluminized zinc coil, which is a steel coated with a mixture of 55% aluminum, 43.4 zinc and 1.6 silicon through a hot-dip aluminized zinc process. The aluminum-zinc alloy protects the base steel from corrosion and rust. It has many favorable characteristics, such as high heat resistance, excellent corrosion resistance, excellent formability, high reflectivity, etc. It is therefore suitable for most applications, including extreme environments.

Hot-dip aluminum-zinc plated steel plate is also called aluminum-zinc plated plate, aluminum-zinc plated natural color plate, aluminum-zinc plated fingerprint resistant plate and aluminum-zinc plated light plate. As the surface coating of the plate is an alloy composed of aluminum, zinc and other trace elements, it has outstanding corrosion resistance and gradually replaces galvanized plate. Aluminum-zinc plated plate is mainly used for steel structure roof, wall surface, switch cabinet body and household appliance board.